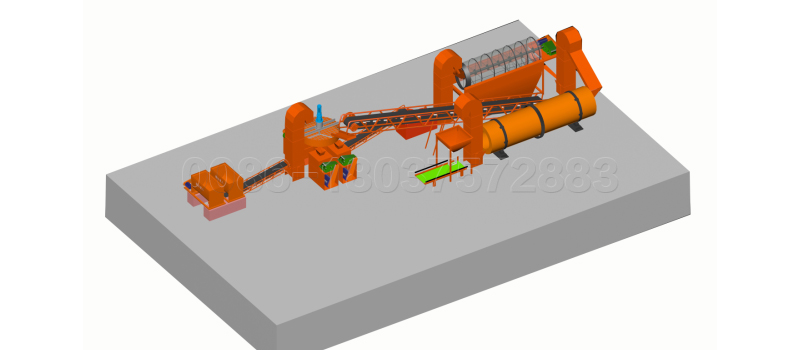

Process introduction of inorganic organic fertilizer extrusion granulation production line:

- Add the qualified raw materials into the mixer according to the ratio requirements and mix them evenly.

- Transport to the disc feeder, and remove the ferrous materials from the material during the transportation process.

- The material in the disc feeder evenly enters the extrusion granulator.The material is forced to pass between the two pressure rollers to be squeezed into flakes. The flakes are broken into pieces by the coarse crusher under the pressure rollers. Screening; the materials on the screen continue to be crushed and screened.

- The semi-finished products are transported to the finished product screening machine; the fine particles after screening are directly returned to the disc feeder,the large particles are crushed by the crusher and then returned to the disc feeder.

- The qualified products after screening are transported to the automatic packaging scale for weighing, packaging and storage.

The production of compound fertilizer by extrusion granulation process has the following advantages and disadvantages

- Extrusion granulation does not require heating and humidification of the materials, which saves investment and energy, and can also be adapted to the granulation of ingredients containing heat-sensitive materials, such as ammonium bicarbonate and certain organic fertilizers.

- No waste water or waste gas is discharged outside during the production process, and it will not pollute the environment.

- The extrusion granulation process is short, easy to operate, easy to realize automatic production control, and improve production efficiency.

- There are no special requirements on the properties and particle size distribution of the raw materials, so the source of raw materials is relatively wide.

- The production is more flexible, and the product plan can be changed at any time, which is conducive to the production of special fertilizers in small batches.

- The product has uniform particle size distribution, no segregation or agglomeration.

- The shape of extrusion granulation products is not as round as the particles produced by traditional methods such as drum granulation and slurry granulation; if chemical reactions occur between the ingredients in the product particles, the particles may collapse.

According to the requirements of customers, we can design 10,000-500,000 tons of organic fertilizer production line and workshop design, provide complete sets of organic fertilizer equipment, BB fertilizer production equipment, organic and inorganic fertilizer equipment, liquid fertilizer equipment, urea-based compound fertilizer equipment, extrusion Fertilizer pressing equipment and high-humidity material drying and fermentation equipment such as chicken manure.